Cabinet Door Clamping System

What is it?

A build-your-own cabinet door clamping station.

We have developed a cost effective system with the necessary pneumatic clamps, hoses, fittings, and parts needed to create your own cabinet door clamping station.

The only thing you need in order to complete the system is to create your own table as large as you like to fit the space that you work in. Whether you are in a big woodworking shop, or just working out of a small space in your garage. This clamping system can be adapted to any space, and runs off of any compressed air system.

There are few items that are not provided you would need to Source yourself such as the table itself, a female air hose connector compatible with they are hoses you use in your own shop. More information on how the system set up an additional parts needed I'll be explained step-by-step in video coming soon.

Clamping table Specifications

3/4” thick material (recommend domestic double sided UV plywood for stability)

Hole configuration is 20mm diameter holes, at 48mm on center

Lay that pattern across a whole sheet as large as you like for your needs

We recommend you have a CNC machine drill the holes for this table to ensure the system operates with minimal issues. As the table sizes increase the more important it is to have a CNC machine accurately drill the layout.

See the bottom of this page for a list of CNC shops in the USA that we recommend for setting up your table.

Cabinet System Table setup Tips

Initial setup

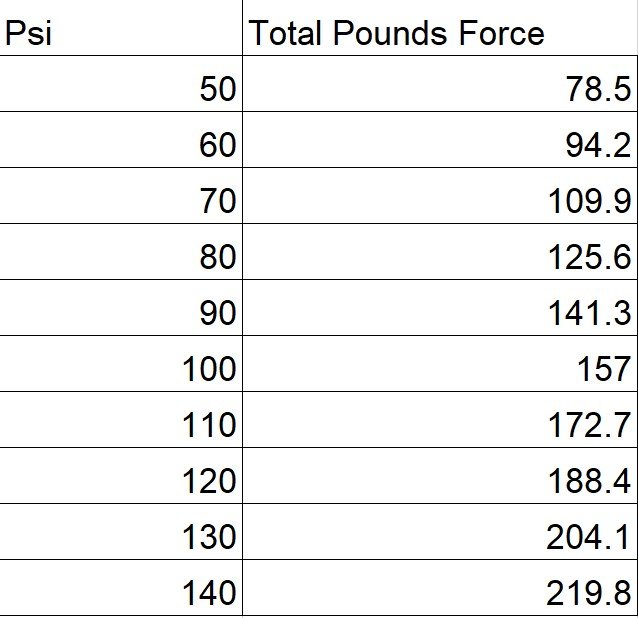

PSI Clamping force pressure ratings

Although this is accurate please understand the information on this table is a calculated approximation.

The force data can vary due to factors but not limited to:

length of hose

compressor system

loose connections

number of clamps connected on a single system

CNC Shop Contact List

Below is a list of Shops around the USA that have the CNC capability for machining your table layout. We can only provide basic contact information to help you reach out. Each shop has their own rates for their time, you must contact them for their pricing information directly.

James (Fourth Generation Craftsman)

Gilbert, AZ - Fourthgenerationcraftsman@gmail.com - 480.861.9372

Tim (True trade Carpentry)

Hackettstown, NJ - Truetradecarpentry@icloud.com - 908.223.1388

Jared (JLW Innovation)

Carthage, MO - jared@cncdesign.us / Jared Wilkinson - 417.793.1219

Marcus (Stromburg Built ,LLC)

Buffalo, MN - marcus@strombergbuilt.com - 612.812.5800

Tony (TS Carpentry)

Golden, CO - Tony@tscarpentry.com - 303.478.4355

Justin (Rustic Grain Design)

Tampa, FL - Info@rusticgraindesigns.com - 813.356.8594

Oscar (Pastence Custom Woodwork and Design)

Glenview, IL - Info@pastence.net

Ingenious Design & Construction

Torrance, CA - igdesignla@gmail.com

Adamski Fine Woodworking

Tampa, FL - Adamskifinewoodworking@gmail.com

Ryan Smythe

Rifle, CO - fabricator@westslopecnc.com - 970.274.0518

Cliff Williams

Wichita, KS - cw@homelandcs.com - 316.304.8329

David Whitley (Beveled Timber Custom Woodwork)

Hartland, WI - beveledtimber@gmail.com

Dave Nichols

Evansdale, IA - nicholsconstruction1@gmail.com - 319.234.2275

Cameron Pile

Charlottesville, VA - cameron@roarkstudio.com

Ben Haug

Youngstown, OH - Haugcabinetdesign@gmail.com - 330.727.4804

Kevin Lamb

Natick, MA - klamb@buildstillwater.com - 508.725.7572

Elwin Kershaw

Medicine Hat, Alberta Canada - elwinkershaw@gmail.com - 403.979.1337alex@jamesrosebespoke.co.uk

Trevor Pappas

Santa Rosa, CA. - pappaswoodworks@gmail.com - 707.230.2052

Steven Ward

Edmond, OK - Steven@TheRoyalOakie.com - 405.896.5770

Alex Preece

Nottingham, UK - alex@jamesrosebespoke.co.uk - +447889237461

James Black ( James Black Stag Boards LLC )

St Clair, MI - Stagboardsllc@gmail.com - 989.387.9713

We are always updating the information here and keep checking back to see if there more options posted in your area. Also if you run a CNC shop and want to be a part of this list, click the signup button below!